- GST NO. : 27AAACH2731C1Z5

- Send Email

+91-9819088822 Call / WhatsApp |

Drop us a line |

Heating, Drying & Cooling Machines

Leading Manufacturers, Wholesaler and Importer of Automatic Belt Drying Machine, Automatic Drying Machine for Leather Goods, Chill Setter Conveyor for PU Footwear, DR-600 Dryer and Reactivator Machine, FM-400 Pneumatic Fusing Machine, Giotto EDGE Inking and Strip Dryer, Heat Setting Chiller Conveyor Machine, Industrial Shoe Chiller Machine, Leather Goods Drying Oven, Wrinkle Chaser 270 Thermoironing Machine, Wrinkle Chaser 271 Thermoironing Machine, Wrinkle Chaser 272 Thermoironing Machine and Wrinkle Chaser 273 Thermoironing Machine from Mumbai.

| Business Type | Manufacturer, Supplier, Importer |

| Machine Type | Belt Drying |

| Function | Moisture Removal, Surface Stabilization |

| Automation | Continuous Belt Feed |

| Material Compatibility | Leather, PU, Synthetic Belts |

| Integration | Modular Job Line Compatible |

| Application | Post-inking, Gluing, Finishing |

| Build Quality | Industrial-grade, Energy Efficient |

Industrial-grade automatic drying machine designed for leather belts and strips. Ensures consistent moisture removal and surface stabilization post-inking, gluing, or finishing. Ideal for integration into modular belt production lines. Offers uniform drying speed, energy-efficient operation, and compact layout for streamlined workflow.

| Business Type | Manufacturer, Supplier, Importer |

| Machine Type | Automatic Drying |

| Function | Moisture Removal, Surface Stabilization |

| Material Compatibility | Leather, PU, Synthetic Goods |

| Operation | Continuous Feed, Automatic Control |

| Usage | Belts, Wallets, Bags, Accessories |

| Integration | Modular Job Line Compatible |

| Build Quality | Industrial-grade, Energy Efficient |

Industrial-grade automatic drying machine designed for post-treatment moisture removal in leather goods production. Ideal for belts, wallets, bags, and accessories. Ensures consistent drying speed, energy-efficient operation, and smooth material handling. Suitable for integration into modular finishing lines or standalone use.

| Business Type | Manufacturer, Supplier, Importer |

| Machine Type | Chill Setter With Conveyor |

| Function | Post-press Cooling And Stabilization |

| Production Rate | 150 Pairs/hour |

| Daily Output | 1000 Pairs In 8 Hours |

| Cooling Logic | Accelerates Adhesive Polymerization And Shape Retention |

| System Compatibility | Rink System Compatible |

| Application | PU Sole Footwear, Heat-treated Shoes |

| Dimensions | 100 X 205 X 168 Cm |

| Net Weight | 480 KG |

| Gross Weight (Crate) | 600 KG |

| Gross Weight (Cage) | 750 KG |

| Build Quality | Industrial-grade, High-volume Ready |

High-efficiency chill setter with integrated conveyor system designed for rapid cooling and stabilization of footwear post sole pressing. Accelerates polymerization of water-based adhesives and ensures perfect sealing. Ideal for fast-cycle production environments. Compatible with rink systems and built for consistent performance across PU sole applications.

| Business Type | Manufacturer, Supplier, Importer |

| Model | DR-600 |

| Machine Type | Dryer And Reactivator |

| Function | Adhesive Reactivation + Moisture Removal |

| Material Compatibility | Leather, Synthetic, Multi-layer |

| Operation | Semi-automatic Heat And Airflow Control |

| Application | Sole And Upper Prep |

| Efficiency | Uniform Drying And Bonding |

| Build Quality | Industrial-grade Components |

| Usage | Footwear Manufacturing |

| Maintenance | Easy Access For Cleaning And Servicing |

DR-600 dryer and reactivator machine designed for efficient adhesive reactivation and moisture removal in footwear production. Ideal for prepping shoe soles and uppers before assembly. Combines controlled heat and airflow to ensure uniform drying and optimal bonding conditions. Suitable for leather, synthetic, and multi-layer materials.

| Business Type | Manufacturer, Supplier, Importer |

| Model Number | FM-400 |

| Machine Type | Pneumatic Fusing |

| Power | 3 KW |

| Weight | 200 KG |

| Operation | Pneumatic |

| Capacity | 400 Pieces Per Hour |

| Pressure | 6 Bar |

| Efficiency | High-speed Bonding |

| Applications | Garments, Footwear, Laminated Materials |

| Build Quality | Industrial-grade Construction |

FM-400 pneumatic fusing machine designed for high-volume bonding applications. Operates at 3 KW power with 6 bar pressure, delivering up to 400 units per hour. Built for consistent performance with industrial-grade durability. Ideal for garment, footwear, and laminated material processing.

| Business Type | Manufacturer, Supplier, Importer |

| Machine Type | Edge Inking And Drying Oven |

| Model | Giotto |

| Function | Inking And Drying For Strips |

| Edge Compatibility | Straight And Curved |

| Drying Units | 4 Integrated Chambers |

| Max Temperature | 150°C |

| Transport System | Nonstick Belt |

| Speed Control | Adjustable Transport Speed |

| Temperature Control | Electronic |

| Humidity Control | Reduced Internal Humidity |

| Fan System | New-generation Airflow |

| Integration | Tecno System Working Line |

| Optional Add-on | Conveyor Extension |

| Usage | Leather Strips, Belts, Accessories |

High-performance edge inking and drying oven designed for straight or curved leather strips. Integrated with Tecno System job lines, it features electronic temperature control, adjustable transport speed, and four drying units for uniform results. Equipped with nonstick belt transport and advanced fan system to reduce internal humidity. Optional conveyor available for extended feed.

| Business Type | Manufacturer, Supplier, Importer |

| Machine Type | Heat Setting Chiller Conveyor |

| Function | Post-lasting Shape Stabilization |

| Production Rate | 250 Pairs/hour |

| Daily Output | 2000 Pairs (8 Hours) |

| Temperature Control | Up To 200°C / 392°F |

| Conveyor Speed | Adjustable From 1' To 10 |

| Ironing Chamber | Stainless Steel |

| System Compatibility | Rink System Compatible |

| Air Consumption | 80 L/min At 6 BAR |

| Net Weight | 370 KG |

| Gross Weight (Crate) | 460 KG |

| Gross Weight (Case) | 550 KG |

| Dimensions | 95 × 230 × 154 Cm |

High-performance heat setter with stainless steel ironing chamber and adjustable conveyor speed for precise post-lasting stabilization. Compatible with rink systems and designed for consistent temperature control up to 200°C. Ideal for high-volume footwear production with fast cycle times and clean finish. Compact footprint with efficient air consumption and robust build.

| Business Type | Manufacturer, Supplier, Importer |

| Machine Type | Shoe Chiller And Glue Stabilizer |

| Function | Glue Aggregation, Shape Retention, Mold Prevention |

| Cooling System | Dual-track Air Circulation With Auto Unfreezing |

| Temperature Range | Down To -30°C (instant -20°C Reach) |

| Compressor | Imported, High-power |

| Belt Material | Special Compound With Refrigeration Control |

| Insulation | Double-sided Concentrated Shell Insulation |

| Customization | Size Options Available Per User Requirement |

| Power | 3 KW |

| Air Pressure | 0.5 MPa |

| Voltage | 380V / 50Hz |

| Machine Size | 3380 X 900 X 1500 Mm |

High-performance shoe chiller machine designed for rapid glue stabilization and post-delasting shape retention. Features imported compressor, dual-track cooling air, and automatic unfreezing system for fast refrigeration and consistent molding. Special belt material with refrigeration regulation ensures mold-free jointing. Double-sided heat insulation reduces energy consumption. Custom sizes available to suit production needs.

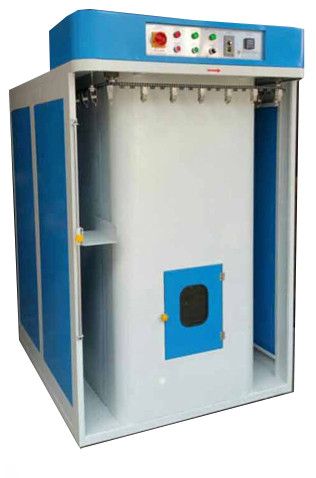

| Business Type | Manufacturer, Supplier, Importer |

| Machine Type | Leather Drying Oven |

| Function | Moisture Removal, Surface Stabilization |

| Max Temperature | 80°C |

| Transport System | Nonstick Belt With Speed Control |

| Temperature Control | Electronic |

| Airflow System | New-generation Fan |

| Humidity Control | Reduced Internal Humidity |

| Material Compatibility | Bags, Wallets, Belts |

| Optional Add-on | 1-meter Front Extension |

| Build Quality | Compact, Energy Efficient |

| Usage | Leather Finishing, Post-treatment Drying |

Industrial drying oven designed for leather goods such as bags, wallets, and belts. Features electronic temperature control, adjustable transport speed, and nonstick belt system for smooth material handling. Equipped with a new-generation fan for efficient airflow and reduced internal humidity. Optional front extension available for increased drying length.

| Business Type | Manufacturer, Supplier, Importer |

| Machine Type | Thermoironing And Wrinkle Removal |

| Model | Series 270 |

| Stations | Dual - Steam Roller + Pounding Hammer |

| Steam Control | Pedal-activated, Up To 4 M³/h |

| Air Temperature | Adjustable Up To 550°C / 1022°F |

| Boiler | Stainless Steel, Patented |

| Air Flow | Variable Speed |

| Interface | Digital Temperature Readout |

| Ergonomics | Curved Base For Boot Handling |

| Functionality | Steam Softening, Hot Air Ironing, Hammer Pounding |

| Efficiency | Reduced Consumption During Idle |

| Safety | Resistance Protection In Low-air Conditions |

| Application | Footwear Upper Finishing And Wrinkle Removal |

Advanced thermoironing machine designed for wrinkle elimination and upper finishing in footwear production. Features dual emplacements—one with heated rollers using hot air and steam, and another with a pounding hammer for enhanced shaping. Steam-only mode activated via pedal for softening, followed by hot air ironing. Ergonomic base curvature supports all boot types. Patented stainless steel boiler with digital temperature control up to 550°C ensures precision and safety.

| Business Type | Manufacturer, Supplier, Importer |

| Machine Type | Thermoironing And Wrinkle Removal |

| Model | Series 271 |

| Stations | Steam Roller Emplacement |

| Steam Output | Adjustable Up To 4 M³/h |

| Air Temperature | Up To 550°C / 1022°F (digital Display) |

| Boiler | Patented Stainless Steel |

| Control System | Electronic With Digital Readout |

| Steam Mode | Pedal-activated Softening |

| Air Mode | Auto-switch For Ironing |

| Ergonomics | Curved Base For Boot Handling |

| Efficiency | Reduced Consumption During Idle |

| Safety | Resistance Protection In Low-air Conditions |

| Application | Footwear Upper Finishing And Wrinkle Elimination |

Thermoironing machine designed for wrinkle elimination and upper finishing in footwear production. Equipped with ironing roller, hot air and steam system, and pedal-activated steam-only mode for softening. Patented stainless steel boiler with digital temperature control up to 550°C ensures precision and safety. Ergonomic base curvature supports all boot types. Reduced consumption during idle and built-in resistance protection enhance operational efficiency.

| Business Type | Manufacturer, Supplier, Importer |

| Machine Type | Thermoironing And Wrinkle Removal |

| Model | Series 272 |

| Stations | Dual - Steam Roller + Pounding Hammer |

| Steam Output | Adjustable Up To 4 M³/h |

| Air Temperature | Up To 550°C / 1022°F (digital Display) |

| Boiler | Patented Stainless Steel |

| Control System | Electronic With Digital Readout |

| Steam Mode | Pedal-activated Softening |

| Air Mode | Auto-switch For Ironing |

| Ergonomics | Curved Base For Boot Handling |

| Efficiency | Reduced Consumption During Idle |

| Safety | Resistance Protection In Low-air Conditions |

| Application | Footwear Upper Finishing And Wrinkle Elimination |

Advanced thermoironing machine for wrinkle elimination and upper finishing in footwear production. Equipped with ironing roller, pounding hammer, and dual-mode steam/hot air system. Pedal-activated steam softening followed by hot air ironing ensures precise shaping. Patented stainless steel boiler with digital temperature control up to 550°C. Ergonomic base curvature supports all boot types. Designed for reduced consumption and automatic resistance protection.

| Business Type | Manufacturer, Supplier, Importer |

| Machine Type | Thermoironing And Wrinkle Removal |

| Model | Series 273 |

| Stations | Steam Roller Emplacement |

| Steam Output | Adjustable Up To 4 M³/h |

| Air Temperature | Up To 550°C / 1022°F (digital Display) |

| Boiler | Patented Stainless Steel |

| Control System | Electronic With Digital Readout |

| Steam Mode | Pedal-activated Softening |

| Air Mode | Auto-switch For Ironing |

| Ergonomics | Curved Base For Boot Handling |

| Efficiency | Reduced Consumption During Idle |

| Safety | Resistance Protection In Low-air Conditions |

| Daily Output | 200 Pairs/hour |

| Air Consumption | 40 L/min At 4 BAR |

| Electric Power | 7 KW |

| Dimension | 44 × 71 × 151 Cm |

| Net Weight | 80 KG |

| Gross Weight (Crate) | 95 KG |

Thermoironing machine designed for wrinkle elimination and upper finishing in footwear production. Equipped with hot air and steam ironing roller, pedal-activated steam mode, and patented stainless steel boiler. Digital temperature control up to 550°C ensures precision. Ergonomic base curvature supports all boot types. Built for reduced consumption and automatic resistance protection. Ideal for high-speed, high-quality finishing.