- GST NO. : 27AAACH2731C1Z5

- Send Email

+91-9819088822 Call / WhatsApp |

Drop us a line |

Lasting, Forming & Moulding Machines

Leading Manufacturers, Wholesaler and Importer of 689-2 Hydraulic Nail Baiting Machine, 710-RCI Pulling Over & Toe Lasting Machine, Back Part Moulding Machine, DL-300 Automatic Delasting Machine, DS-618AM Automatic Toe Lasting Machine, Heel Seat and Side Lasting Machine, Hercules-80 Moccasin Pre Forming Machine and Toe Humidifier Machine from Mumbai.

| Business Type | Manufacturer, Supplier, Importer |

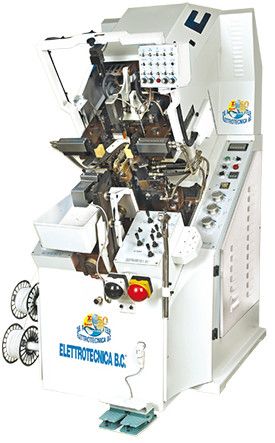

| Model | 689-2 |

| Machine Type | Hydraulic Nail Baiting |

| Application | Trouser Mounting, Garment Finishing |

| Nail Size Compatibility | 6 Mm To 12 Mm |

| Insert System | Removable Matrix For Multi-size Work |

| Loader | Quick-disassembly Nail Loader |

| Verification | Pull-out Matrix For Skin Alignment Check |

| Drive System | Hydraulic-powered Components |

| Reliability | Undergoes Quality And Durability Testing |

| Usage | Men's, Women's, Baby Garments |

| Maintenance | Easy Access And Servicing |

689-2 hydraulic nail baiting machine designed for trouser mounting and multi-size nail application. Equipped with winder and removable inserts for quick matrix change—ideal for men’s, women’s, and baby garments. Supports 6–12 mm nails with fast-loading system and pull-out matrix for skin distribution verification. All moving parts powered by hydraulic system for high reliability and consistent performance.

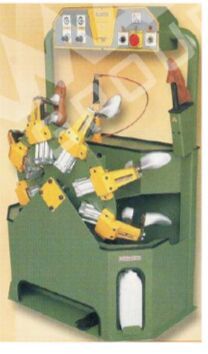

| Business Type | Manufacturer, Supplier, Importer |

| Model | 710-RCI |

| Machine Type | Pulling Over & Toe Lasting |

| Applicator | Adjustable Front/back, Auto Left/right, Interchangeable Head |

| Pincers | 9 Total, 5 Revolving, Single Opening |

| Last Support | Double Release With Mechanical Stop Precision |

| Adjustment | External Handles For Last Support, Manometer-based Pressure Control |

| Bands | Independent Side Bands + Teflon Band |

| Wipers | Spoon Wipers, Long-lasting System |

| Speed Control | Horizontal Pincer Opening For Quick Last Changes |

| Tech Features | Optical Projector, Integrated Webcam, Video Program |

| Modular Compatibility | Connects With Mod. 001, 002, 140, 181, 182, 230 |

| Tooling | Toolbox Included |

| Production Capacity | 250 Pairs/hour |

| Electric Power | 3 KW |

| Working Pressure | 5 MPa |

| Dimensions | 114 X 183 X 210 Cm |

| Net Weight | 1100 KG |

| Gross Weight | 1300 KG (with Crate) |

710-RCI full-optional toe lasting machine with TI system, engineered for high-speed vamp pulling and toe shaping. Features adjustable applicators, 9 pincers with 5 revolving units, and dual-release last support for precision stop control. Includes optical projector, integrated webcam, and external adjustment for all pressure zones. Ideal for rapid production across multiple shoe types with programmable settings and modular compatibility.

| Business Type | Manufacturer, Supplier, Importer |

| Machine Type | Back Part Moulding |

| Stations | 2 Hot + 2 Cold |

| Counter Compatibility | Thermoplastic / Thermoadhesive Coated Uppers |

| Pincers | Pulling Group On Hot Stations |

| Pliers Group | On Each Reactivating Station |

| Control System | Electronic With Digital Temperature Display |

| Seam Visibility | Clear View During Upper Loading |

| Mould Customization | Based On Customer's Last Shape |

| Daily Output | 900-1000 Pairs |

| Absorbed Power | 2.3 KW |

| Dimensions | 148 X 80 X 200 Cm |

| Net Weight | 610 KG |

High-efficiency back part moulding machine equipped with 2 hot and 2 cold stations for precise upper shaping. Includes pulling pincers on hot reactivation stations and pliers group on each reactivating unit. Ideal for thermoplastic and thermoadhesive coated counters. Features digital temperature control, clear seam visibility, and custom moulds shaped to customer’s last. Designed for high-volume footwear production.

| Business Type | Manufacturer, Supplier, Importer |

| Model | DL-300 |

| Machine Type | Automatic Delasting |

| Production Capacity | 300 Pairs/hour |

| Daily Output | 2400 Pairs Per 8 Hours |

| Pad Control | Fully Adjustable With Auto Height Adjustment |

| Last Peg | Inclined For Boot Compatibility |

| Air Consumption | 100 L/min At 6 BAR |

| Dimensions | 84 X 45 X 136 Cm |

| Net Weight | 216 KG |

| Gross Weight | 260-287 KG (with Crate) |

| Usage | All Shoe Styles And Materials |

| Efficiency | High-speed Last Removal |

DL-300 automatic delasting machine designed for high-speed last pulling across all shoe styles and materials. Features fully adjustable pad with automatic height control for maximum adherence. Inclined last peg supports boot processing. Delivers consistent output with minimal manual effort—ideal for high-volume footwear production.

| Business Type | Manufacturer, Supplier, Importer |

| Name | DS-618AM Automatic Toe Lasting Machine |

| Model | DS-618AM |

| Machine Type | Automatic Toe Lasting With Cementing |

| Motor Power | 2.2 KW |

| Heating Power | 1.0 KW |

| Working Voltage | 380V / 50Hz |

| Working Pressure | 5 MPa |

| Efficiency | 1600 Pairs Per 8 Hours |

| Net Weight | 1135 KG |

| Application | Children, Sports, Formal, Riding, Mountaineering, Work Shoes |

| Operation | Claw-based Vamp Molding |

| Features | Easy Operation, High Output, Stable Quality |

DS-618AM automatic toe lasting machine with cementing function designed for precise vamp clamping and sole molding. Features claw-based molding mechanism for smooth vamp-to-last attachment. Delivers high efficiency, stable quality, and easy maintenance. Suitable for children’s shoes, sports shoes, formal footwear, riding boots, mountaineering shoes, and specialized work shoes.

| Business Type | Manufacturer, Supplier, Importer |

| Machine Type | Heel Seat And Side-lasting |

| Size Range | Paris Point 18 To 54 |

| Footwear Types | Sports, Men's, Women's, Children's |

| Heel Height | Compatible With All Heel Profiles |

| Cementing System | Programmable Seat And Side Application |

| Toe Lasting Compatibility | Works With Joint And Non-joint Systems |

| Interface | Touch Screen Programming |

| Usage | Insole Cementing And Lasting |

| Efficiency | High-speed, Multi-size Adaptability |

| Build Quality | Industrial-grade, Precision Engineered |

Versatile heel seat and side-lasting machine designed for sports and conventional footwear across all sizes and heel heights. Supports Paris point 18 to 54. Compatible with any toe lasting system, including joint lasting setups. Features programmable cement tracking directly onto the insole and a touch screen interface for precise control. Ideal for high-volume, multi-category shoe production.

| Business Type | Manufacturer, Supplier, Importer |

| Model | Hercules-80 |

| Machine Type | Moccasin Pre Forming |

| Stations | 8 Revolving Moulding Stations |

| Lasts | Heated Aluminium |

| Softening Device | Superheated Steam, No Wetting |

| Pounding Tool | Pneumatic, 6500 Blows/min |

| Tool Specs | 450g Weight, 100L/min Air Consumption |

| Power Control | Adjustable Pounding Intensity |

| Stretching Control | Independent Regulators Per Station |

| Application | Moccasin & Clog Uppers |

Hercules-80 revolving 8-station moulding machine designed for pre-forming moccasin and clog uppers. Equipped with heated aluminium lasts and superheated steam softening device for perfect shaping without moisture. Includes pneumatic pounding hand tool delivering 6500 blows/min with adjustable power. Each station features independent stretch regulators for size-specific upper forming.

| Business Type | Manufacturer, Supplier, Importer |

| Machine Type | Toe Humidifier And Reactivator |

| Stations | 2 (sprayer + Hot Air) |

| Function | Toe-cap Steaming And Softening |

| Steam Output | Adjustable Up To 6.5 M³/h |

| Temperature Control | Up To 250°C / 482°F (digital Display) |

| Electric power | 4 KW |

| Air Consumption | 30 L/min At 3 BAR |

| Daily Output | 175 Pairs/hour |

| Dimensions | 54 × 44 × 116 Cm |

| Net Weight | 80 KG |

| Gross Weight | 100 KG (with Crate) |

| Build Quality | Stainless Steel Steam Chamber |

| Application | Footwear Upper Prep Before Lasting |

Toe humidifier machine with dual stations for high-temperature steaming and reactivation of toe caps before lasting. Features stainless steel steam chamber with sprayer and hot air system for rapid softening. Adjustable steam output and temperature via electronic display. Designed for consistent shaping, fast cycle times, and clean operation in footwear production.